How Statis Dock Scheduling is Hindering Warehouses from Building an Agile Supply Chain

Breaking the Barrier

Dock scheduling is a critical component of warehouse operations and the movement of goods throughout the supply chain. Without proper scheduling, shipments can be delayed, resulting in lost revenue, frustrated customers, and decreased operational efficiency. Yet many warehouses still rely on outdated static dock scheduling methods, which can cause significant bottlenecks and inefficiencies.

The Problem with Static Scheduling

Static dock scheduling relies on pre-planned schedules that are not easily adjustable to accommodate unexpected changes. This approach can cause significant delays and bottlenecks, as warehouse operators are unable to adapt to changing conditions or prioritize urgent shipments. Additionally, static scheduling often requires manual data entry, leading to errors and inaccuracies.

Benefits of Dynamic Dock Scheduling

Dynamic dock scheduling, on the other hand, leverages real-time data to optimize dock schedules based on a range of parameters, including shipment size, carrier performance, and historical warehouse data. By implementing a dynamic scheduling approach, warehouses can eliminate bottlenecks and reduce wait times, increasing operational efficiency and reducing costs. Additionally, dynamic scheduling can provide valuable insights into operational performance, allowing for continuous improvements and data-driven decision-making.

Implementing a Dynamic Dock Scheduling Solution

To implement a dynamic dock scheduling solution, warehouses need a comprehensive platform that can manage all aspects of the scheduling process. BiggerPictures offers a dynamic dock management solution that empowers warehouse operators with a range of features, including self-service scheduling, driver self-check-in, carrier tracking, and OpenAPI integration. By leveraging these features, warehouses can optimize their dock management system, reduce errors, and increase customer satisfaction.

Conclusion

In today’s fast-paced logistics environment, warehouses need to be able to adapt quickly to changing conditions and prioritize urgent shipments. Static dock scheduling methods are no longer sufficient to meet the demands of modern supply chain management. By implementing a dynamic dock scheduling solution, warehouses can drive significant improvements in operational efficiency, reduce costs, and increase customer satisfaction. Don’t let static scheduling hold your warehouse back – upgrade to a dynamic dock scheduling solution today.

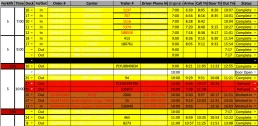

Ready to see how much you could save with BiggerPictures’ dynamic dock management solution? Check out our ROI calculator and discover the potential benefits for your business. With just a few clicks, you can see the impact on your bottom line and determine the potential return on investment. Don’t wait any longer to optimize your dock management system and increase operational efficiency. Try our ROI calculator now and see the difference BiggerPictures can make for your business.